Company

TUSA

Our History

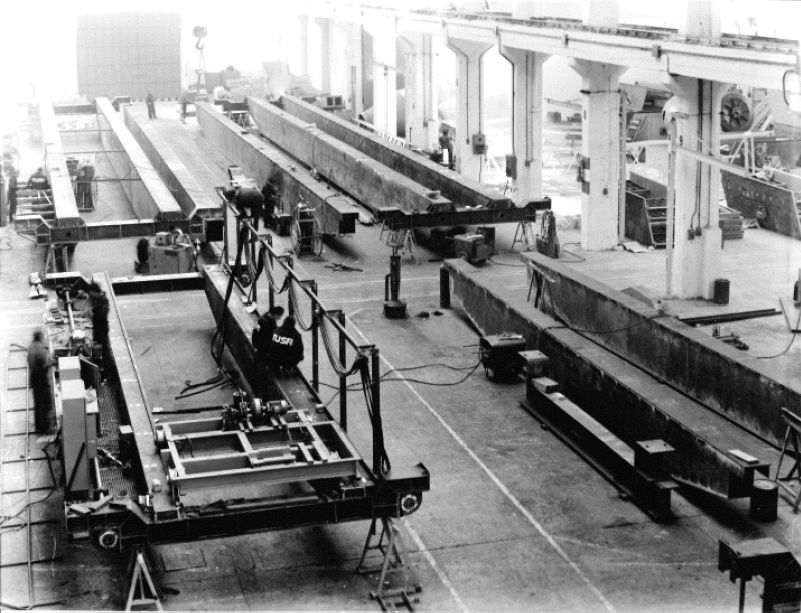

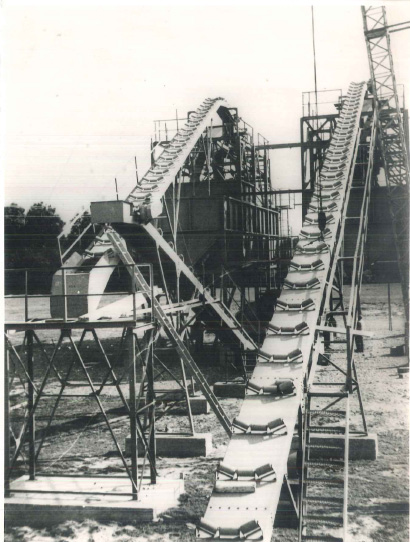

Talleres Unidos, S.A., trading under the name TUSA , was founded in the mid-20th century in modest premises in Zaragoza’s Arrabal neighbourhood. It was devoted to the design and fabrication of conveyor belts, slat conveyors, roller conveyors, bulk fuel storage tanks, silos for fine and coarse aggregates, overhead and gantry cranes, bucket elevators and augers, among others. All of the company’s production served the mining and public works sectors, which were booming at the time.

TUSA’s designs and products made a name for themselves so quickly that the time soon came to move and expand the company’s facilities in order to meet the constantly growing demand for them. TUSA’s main production facility was built in the late 1950s, and it was such a striking building for the time that it soon became a Zaragoza landmark.

MANUFACTURING

Our Designs

Putting its faith in constant technical development, TUSA began to design and produce screens for aggregates, coal, fine materials, etc., allowing it to expand its range of products to serve the sector in which it had excelled since the very beginning. Such was this Aragonese company’s spirit of technical and manufacturing excellence that by the 1960s, TUSA manufactured everything from conveyor belts and small electrical components to overhead and construction cranes, and truck-mounted and crawler excavators.

The crawler excavator models that were entirely made in Spain by TUSA in the 1960s were extraordinarily well received by both the domestic and export markets.

TUSA entered the 1970s holding its position in the market after being taken over by the French company Poclain a few years earlier. However, in the mid-1980s, Poclain decided to divest itself of its industrial activity in Iberia, the result of which was that Talleres Unidos, S.A. ceased to operate.

It was then that the TUSA of today was refounded through the spirit of a number of people who never ceased to believe in the brand and in the profitability of the company. The new entity was christened Transportadores Universales, S.A., but it has kept the TUSA name.

PRESENT DAY

Our Prestige

TUSA’s international image is as highly regarded today as it was when it began in the mid-20th century, or even more so. Its current activity continues to be focused on engineering, design, development, manufacture and assembly of systems for the aggregate, mining and concrete sectors, and industry and material handling in general. However, constant innovation and the search for new markets for its designs and products is in the company’s DNA, which is why TUSA has managed to adapt all its teams to the development of turnkey solutions for the recycling and treatment of all types of waste.

Moreover, TUSA is the only Spanish manufacturer of conveyor belts for ski resorts. TUSA’s extensive engineering experience is behind the success of its conveyor systems that are now being used at leading ski resorts across Europe.

PRESENT DAY

Recognised Brand

TUSA is today a well known and recognised brand because of the wide experience of its management team, the personal service offered to customers, the flexibility of its production resources and the high quality of its products. TUSA can adapt a standard product or develop special machinery to meet the specifications of a particular project, while providing the best technical and cost solution.

Transportadores Universales, S.A. enjoys great prestige in the sector and is one the leading Spanish manufacturers of belt conveyor systems, screens, concrete batching plants, feeders, trommel screens, hoppers, classifiers, washing drums and mobile units, among others in a very extensive list that TUSA engineering adapt to suit different materials according to customer requirements.

What sets TUSA apart is the full range of services the company offers:

Engineering and Design

From the very beginning, the entire TUSA engineering department is focused on satisfying customers’ needs and achieving the best possible result for each project. TUSA is proud of its proficiency for the design and development of new products and ability to adapt standard products to customer specifications in order to offer the best possible technical and economic solution. Also outstanding is TUSA’s skill when it comes to designing and developing special machinery, thanks to the extensive experience of its management team and the flexibility of its production resources.

After-Sales Service

TUSA has a large storage facility filled with items ready for dispatch. In most cases, spare parts can be delivered within 24–36 hours. TUSA is at the ready to provide any urgent repairs our customers may require. The company’s presence on international markets is constantly ensured through a global network of distributors and partners, as well as through our participation in the leading trade events in the sector and our collaboration with associations in the trade exhibitions and events industry.

Development and Manufacturing

TUSA’s innovation in the production systems combined with our extensive experience in the metallurgical industry allows us to meet important goals in terms of quality and lower costs.

TUSA Assembly

TUSA has its own team of experienced fitters and offers its customers the possibility of overseeing the installation process, including commissioning.

The company’s presence on international markets is constantly ensured through a global network of distributors and partners, as well as through our participation in the leading trade events in the sector and our collaboration with associations in the trade exhibitions and events industry.

Services

WE OFFER FIRST-CLASS TECHNICAL SERVICE YOU CAN TRUST.

PRODUCTIVITY

Maximise productivity and efficiency.

COSTS

Reduce operating and maintenance costs.

OPTIMISATION

Optimise your maintenance schedule.

TIME

Detection and treatment of weak spots as early as possible.

EN

EN

Español

Español Français

Français