CONCRETE PLANTS

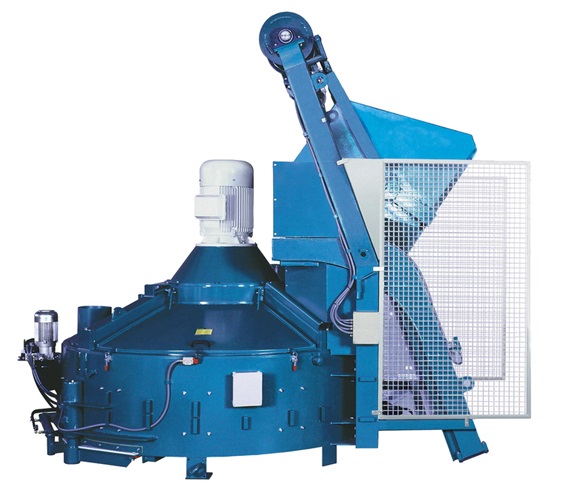

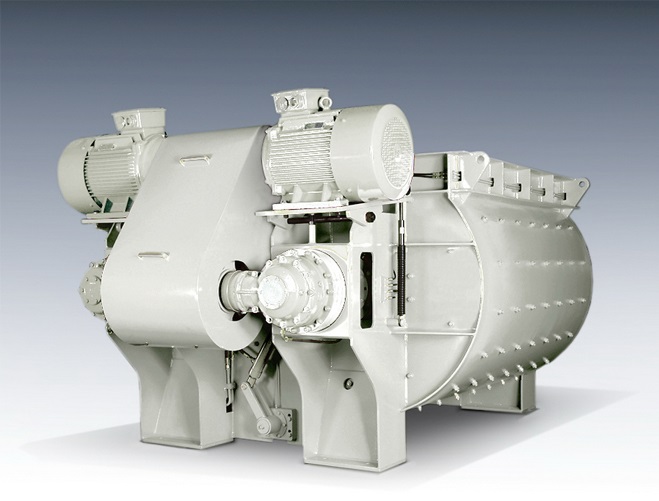

Mixers

Introduction

Mixers designed and experienced in mixing all types of concrete, dry mortars, monolayer, cementitious adhesives, refractory concrete, additives, etc.

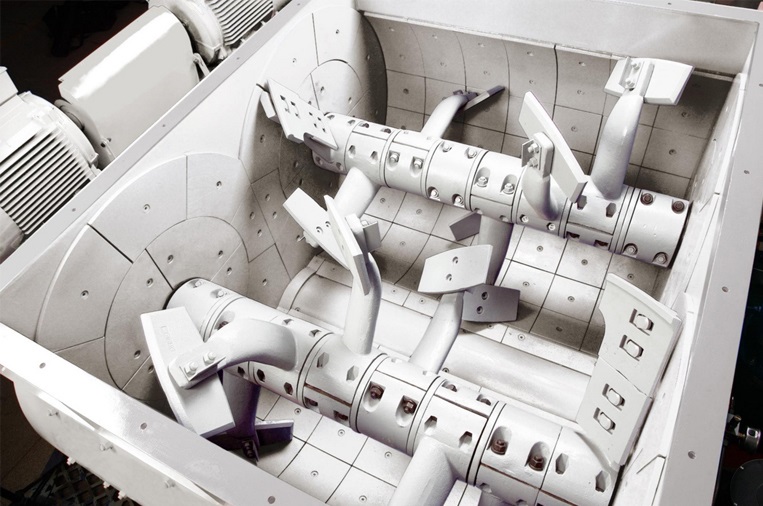

Attention to detail

- Large inspection hatches to provide an adequate view and easy access to the mixer.

- Spacious cover for better distribution of the inlets.

- Motors assembled on supports to maintain tension of belts.

- Different water distribution systems designed for efficient dispersion, according to the materials used.

- Bearings separated from seals for much easier maintenance.

Mixer series features

- Hydraulic opening of discharge hatches.

- Interchangeable bottoms and anti-wear liners.

- Reversible mixing paddles.

- Toothed crown with specific heat treatments.

- Round mixing arms in special steel.

- Water distribution ring with nebulizing diffusers.

- Extensive inspection coverage.

- Safety devices according to EC standards.

Advantages

- Reduced mixing time.

- Minimum discharge time.

- Savings in cement amounts.

- Homogeneous mixing.

- Minimum operating and maintenance costs.

Load skip series features

- Anti-fall safety device.

- Rail tilt up to 90º.

- Ribbed drum with independent cables.

- Large cable winding diameter.

- Aggregate inlet with anti-dust hatch.

- Limit switch in load/standby/unload positions.

- Emergency end of run.

Advantages

- Minimum skip loading height.

- Limited skip pit.

- Fast and efficient unloading.

- Front unloading hatch.

- Single-level cable coiling.

EN

EN

Español

Español Français

Français